VINYL PRESSING

In our vinyl pressing plant in Augsburg Germany, we press records for a large number of national and international labels, artists and bands. We guarantee the highest quality, sustainability and transparent communication. We can also press recycled vinyl and colored vinyl with an extensive color palette in small runs of 100 pieces or more. Thanks to our extensive supplier contacts, we can also produce unusual packaging, such as tip-on covers, PVC sleeves with screen printing, printed lined inner sleeves and boxes. We will be happy to advise you and work with you to find the right packaging to make your vinyl production something special.

VINYL manufacturing PROCESS

As soon as you have accepted our offer online, by email or by phone, you will receive access to your production folder in our mailbox.org cloud. Here you can upload all audio and graphic files. We also need the delivery authorization from the responsible collecting society (e.g. GEMA). You can follow all further production steps, from master film cutting to pressing and dispatch, at any time via our customer portal.

COSTS & DELIVERY TIMES

Our production time is currently 6-8 weeks (including test pressings) from delivery of all production data and approvals.

Delivery dates are non-binding, but release dates can be arranged with us.

100x 12"

- colored recycled vinyl or black vinyl, 135-140 g

- 1-4-color labels

- Lacquer foil cut A/B

- Electroplating A/B

- 3 test pressings

- White lined inner sleeves

- 4-color cover

- Packaging

- plus.

shipping costs

1160 € plus. VAT.

300x 12"

- colored recycled vinyl or black vinyl, 135-140 g

- 1-4-color labels

- Lacquer foil cut A/B

- Electroplating A/B

- 3 test pressings

- White lined inner sleeves

- 4-color cover

- Packaging

- plus.

shipping costs

1570 € plus. VAT.

500x 12"

- colored recycled vinyl or black vinyl, 135-140 g

- 1-4-color labels

- Lacquer foil cut A/B

- Electroplating A/B

- 3 test pressings

- White lined inner sleeves

- 4-color cover

- Packaging

- plus.

shipping costs

1970 € plus. VAT.

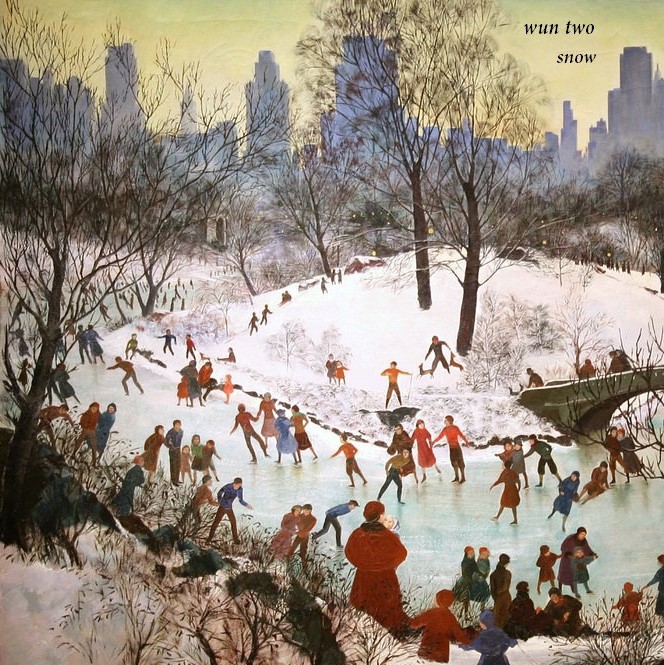

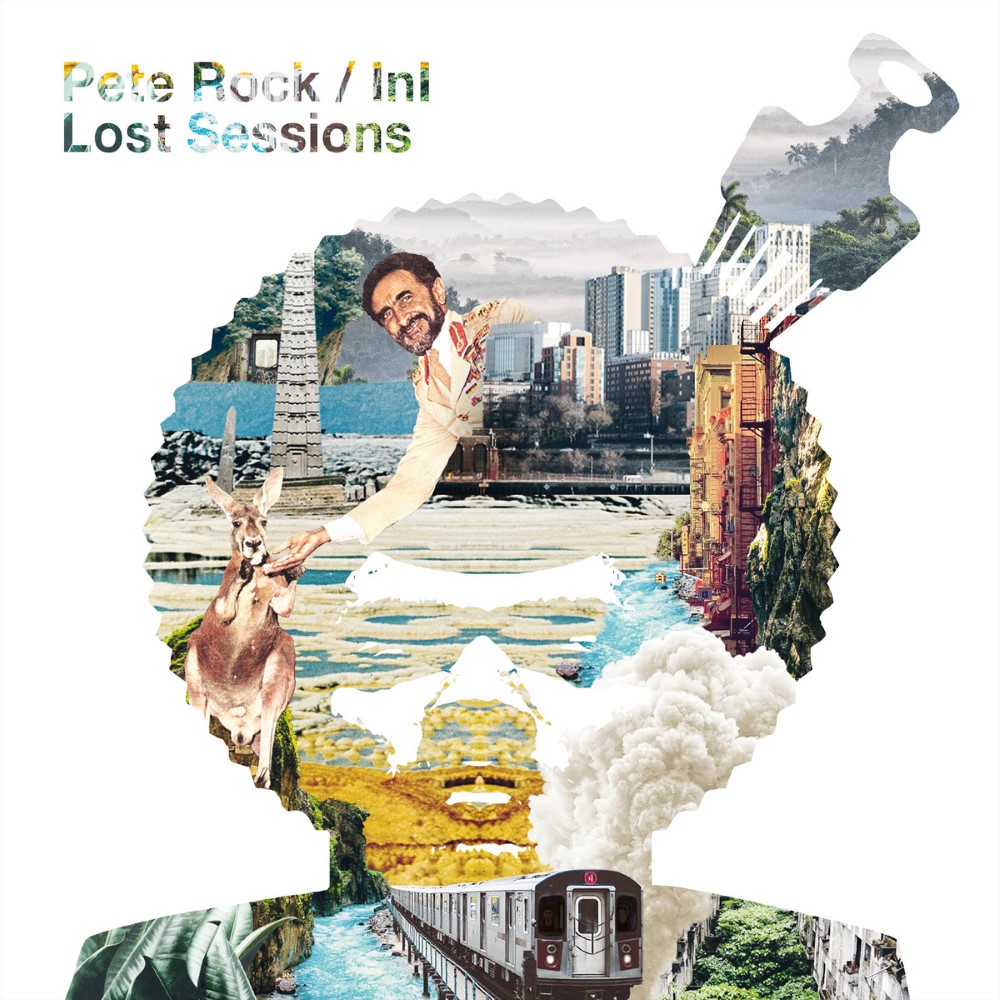

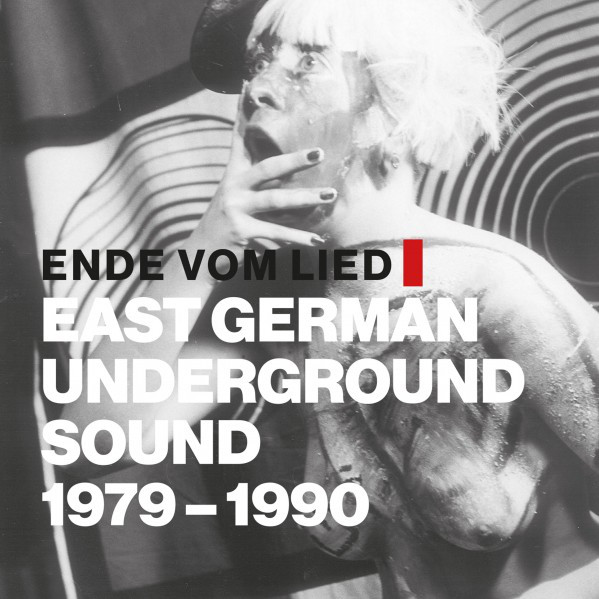

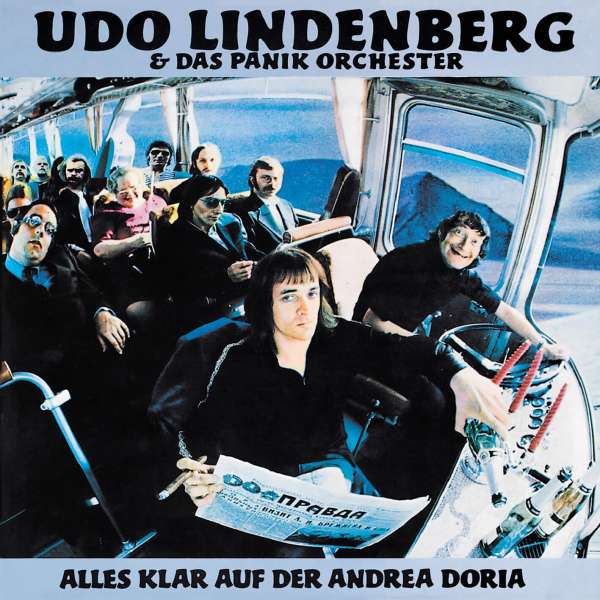

PRESS RECYCLED VINYL

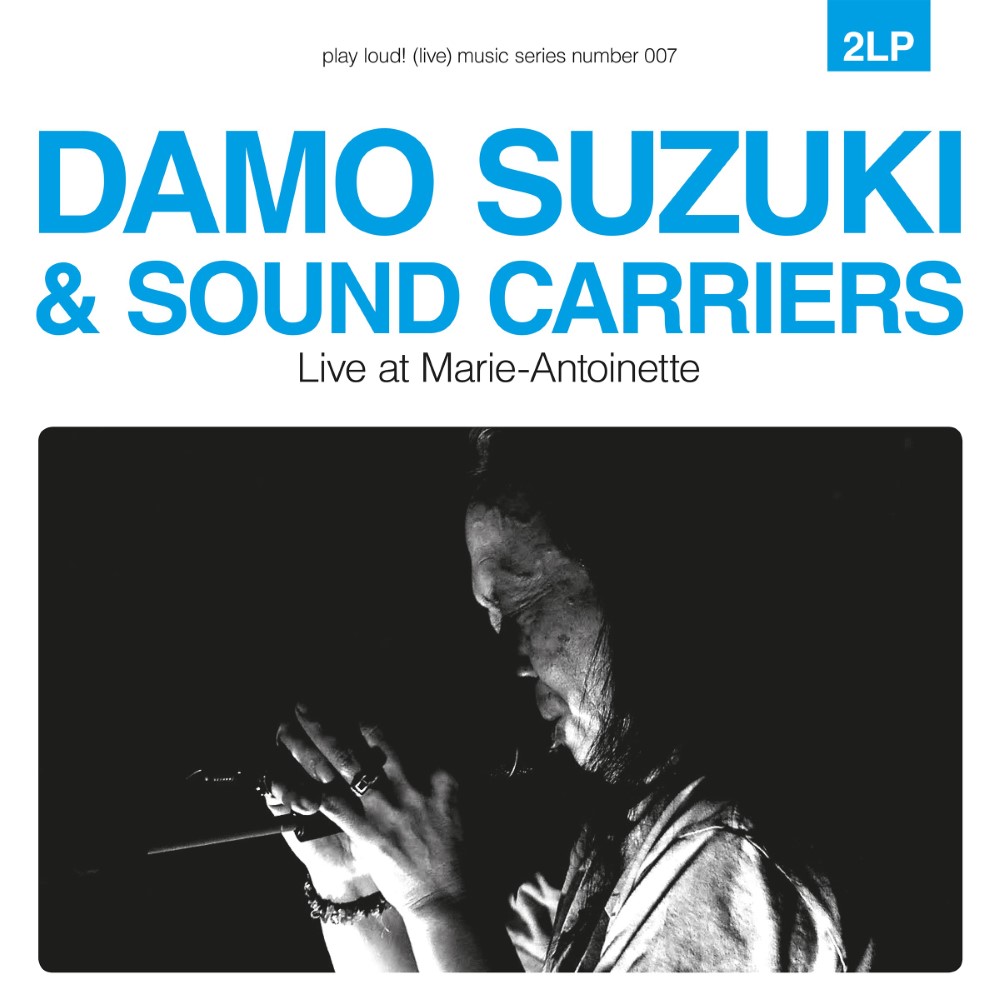

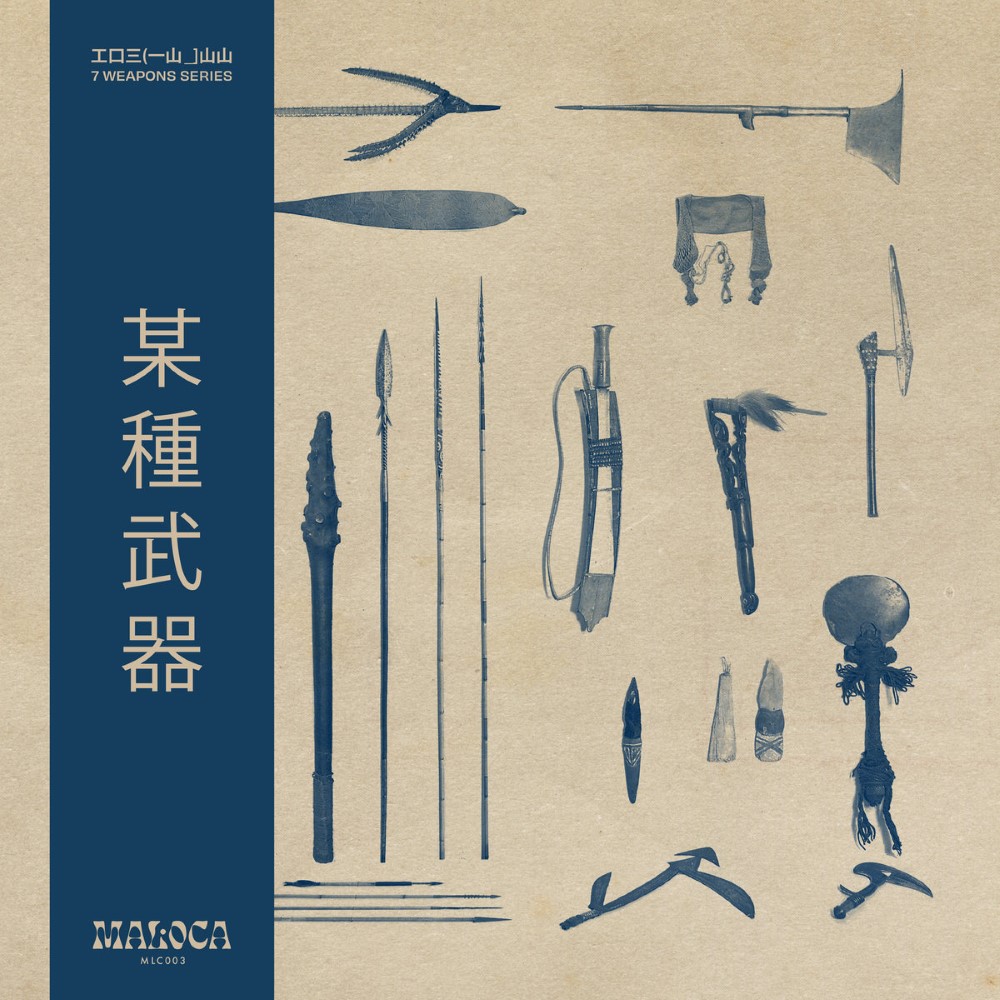

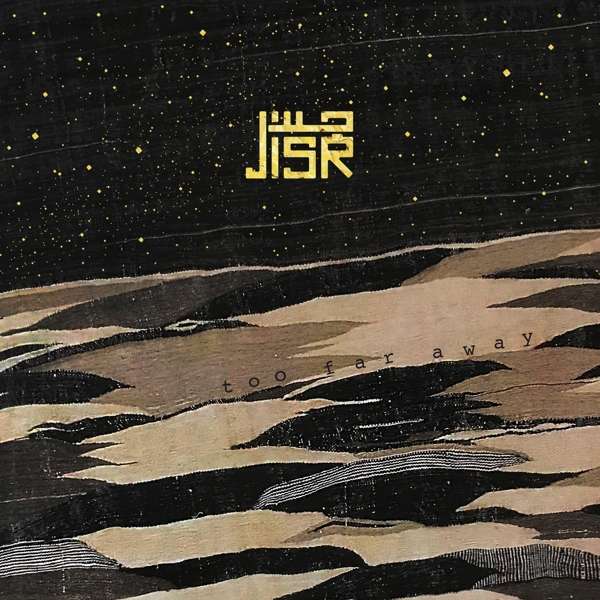

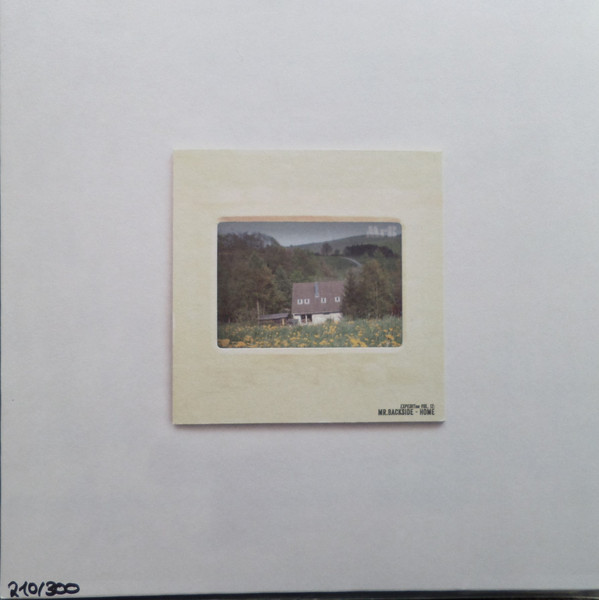

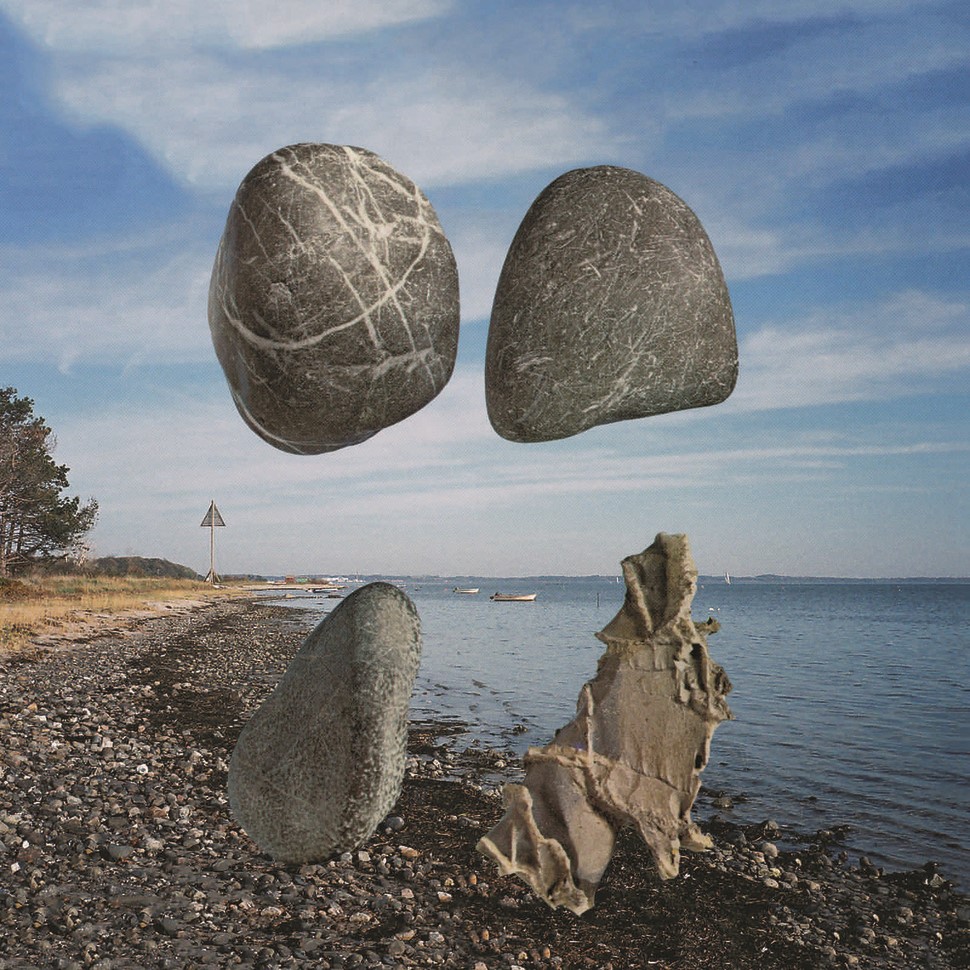

We also offer the option of recycled vinyl. Here, we press your records from 100% recycled vinyl, which is carefully extracted from production waste in our vinyl record manufacturing plant. This allows us to reduce emissions and protect the environment without compromising on quality. In terms of color, you can choose between classic black and a random colorful mix. You can also find sample photos here.

PACKAGING, PRINT SPECIFICATIONS TEMPLATES

Here you will find an overview of some of the possible packaging variants. Simply click on the images to access the corresponding specifications and templates.

Labels

Printed inner sleeve

Cover

Text sheets

Download card

PVC/PE bag

Gatefold Cover

Tip-on cover

Other print products

POSSIBLE PLAYTIMES FOR VINYL PRESSING

| 45 rpm | 33 rpm | |

| 12″ | 6 – 11 minutes | 17 – 22 minutes |

| 10″ | 5 – 7 minutes | 12 – 14 minutes |

| 7″ | 3 – 5 minutes | 5 – 6 minutes |

The longer the playtime and the more bass-heavy the sound, the quieter the record will be. Shorter playing times allow louder cuts (+2 dB – +6 dB), while longer playing times are quieter and can lead to more background noise and sampling distortion.

MASTERING FOR A VINYL PRESSING

Records are analog sound carriers and the sound recording is subject to physical conditions. Each cut of the master lacquer results in sound changes compared to the digital original – however, the greatest differences in frequency response occur when the playback system samples the sound.

Our aim is to transfer the production true to the original. We check every master thoroughly before cutting the master lacquer, and we are happy to make small technical adjustments free of charge. In order to achieve the best possible sound on the finished pressing, it is nevertheless helpful to observe a few rules:

-

- Stick to the recommended playtimes.

-

- Quiet songs with little treble should be placed at the end of the sides.

-

- Avoid stereo components in the bass range below 180 Hz.

-

- Avoid digital distortion and maintain a safety margin of at least -0.5 dB True Peak.

-

- Avoid a treble-heavy mix and use a de-esser if necessary.

-

- Avoid excessive compression/limiting of the sum; an LUFS value of -10 dB is acceptable.

If you don’t have the necessary equipment and experience, we recommend professional mastering. We also offer mastering services in our studio.

TRANSFERING THE AUDIO FILES TO THE PRESSING PLANT

To upload your production data, we will provide you with access to our secure mailbox.org cloud service once you have placed your order. We also accept file hosts such as WeTransfer and Dropbox.

Ideally, you should deliver WAV files in 16-32 bit with sampling rates between 44.1 kHz and 96 kHz. It is best to use the native sampling rate in which the project was originally created. Other digital formats that we accept are FLAC, AIFF, DDP, DAT and CDR. For analog 1/4″ tapes, we also have a perfectly calibrated OTARI tape machine.

Please also send us a track list with page layout and break information. The desired engraving should also be specified when submitting the data.